Rotor blading accessories

In our offer, you will find a wide range of mounting elements. Our extensive material resources and variety of technological processes allow us to promise fast delivery times. We don’t limit ourselves to the production of standardized elements – we guarantee individualized products tailored to the needs of our customers.

-

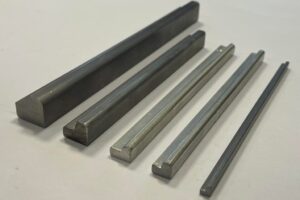

Shims are the main and most popular element in our product portfolio. They are used for blading turbine rotors – mounted in rotor shaft grooves between rotor blades. Their purpose is to evenly fill the free spaces between the rotor blades and tighten the entire blade circumference. Spacers are mainly used for RTB type rotor slots (so-called without locking), which eliminates the need for riveting the last rotor blade in the slot. High-alloy, austenitic, and nickel materials are used for spacer production. We distinguish between full, split, locking, wedges, RCCA, and MHB shims. Our technology and advanced machinery enable us to precisely manufacture spacers of various dimensions and thicknesses.

Shims:

- Full and split (pressed and clean)

- Locking shims

- Wedges

- RCCA

- MHB

-

One of the most popular rotor blading elements produced in our company are sealing strips and caulking wires. Sealing strips are used to secure the medium flowing through the turbine. They are installed in grooved slots using caulking wire, which is upset during installation to compress and lock the sealing strip. Sealing strips and caulking wires are made of high-alloy, austenitic, and nickel materials. We produce caulking wires in all sizes, while sealing strips are available in various tape thicknesses. The most popular tape thicknesses on the market are: 0.3 mm, 0.5 mm, and 0.7 mm. In addition to standard orders, we also manufacture special-shaped sealing strips with variable profiles, such as 1.8/2.5 mm or 2.0/2.5 mm. Our company offers the production of J, I, L, and U-shaped sealing strips of various diameters, ranging from 300 mm to 2000 mm, with a height of up to 16 mm and a thickness of 0.3 mm to 0.7 mm. The length of our strips when unfolded ranges from 650 mm to 8000 mm, or in spiral form to any length specified by the customer.

We are able to produce other shapes of sealing strips that meet the individual needs of our customers. Our company has engineering capabilities that allow us to independently develop tooling for the production of sealing strips with non-standard shapes. To achieve this, we utilize a roller system, which is beyond our standard equipment. This enables us to provide our customers with solutions tailored to their specific requirements and preferences.

-

Axial locking segments serve the purpose of protecting rotor blades from axial displacement along the rotor axis. We don’t limit ourselves to the production of standard types of segments – we also manufacture profiles tailored to the needs of our customers. The technological equipment necessary for the production of axial locking segments is made in-house. Our company specializes in producing segments of various widths, such as segment types: 5, 10, 12, 15, and 20, where the type determines the width of the detail in millimeters. Our segments are made of high-quality stainless steel, guaranteeing durability and strength to our customers. The drawing process, to which our plates are subjected, ensures not only excellent surface quality but also favorable compressive stress conditions. This, in turn, contributes to increasing the strength of our details and ensures a very good surface roughness.

-

Spring tapes are widely used in many industries. Their strength and flexibility allow them to be used to mount even very heavy objects. Stainless steel tapes are resistant to corrosion, sunlight, and temperature changes. In the basic version, we offer stainless steel tapes up to 350 mm wide and up to 2.5 mm thick. Carbon tapes also feature high strength and resistance to variable atmospheric conditions, but their most important characteristic is their conductivity. The most popular materials include C75S (1.1248), C67S (1.1231), and 51CrV4 (1.8159), which we configure to any required dimensions for the customer – providing cutting services to the appropriate length and width. We also fulfill custom orders according to the specifications provided by the customer.

-

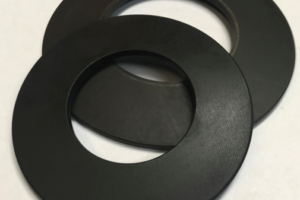

In our product portfolio, we offer coil springs, flat springs, compression springs, and disc springs. Additionally, we fulfill custom orders to meet individual customer needs. The materials we use include typical spring steels and nickel alloys. Disc springs are exclusively manufactured by hot extrusion to the required shape (we do not use mechanical processing technology). Each produced spring undergoes testing of its deflection characteristics relative to the applied force. Upon request, we provide deflection characteristic testing of the spring in an accredited laboratory.

-

We also offer a wide range of assembly accessories. Our assortment includes various products such as: washers, tapes, dowels, screws, nuts, plugs, caps, gaskets, inserts, centering bushings, sliding plates, nuts, screws, spacers, mounting tapes, and many more. We ensure high quality of these elements, which are essential for effective assembly and construction. Regardless of the project or needs, our remaining range of mounting elements is ready to meet the requirements of our customers.

Shims are the main and most popular element in our product portfolio. They are used for blading turbine rotors – mounted in rotor shaft grooves between rotor blades. Their purpose is to evenly fill the free spaces between the rotor blades and tighten the entire blade circumference. Spacers are mainly used for RTB type rotor slots (so-called without locking), which eliminates the need for riveting the last rotor blade in the slot. High-alloy, austenitic, and nickel materials are used for spacer production. We distinguish between full, split, locking, wedges, RCCA, and MHB shims. Our technology and advanced machinery enable us to precisely manufacture spacers of various dimensions and thicknesses.

Shims:

- Full and split (pressed and clean)

- Locking shims

- Wedges

- RCCA

- MHB

One of the most popular rotor blading elements produced in our company are sealing strips and caulking wires. Sealing strips are used to secure the medium flowing through the turbine. They are installed in grooved slots using caulking wire, which is upset during installation to compress and lock the sealing strip. Sealing strips and caulking wires are made of high-alloy, austenitic, and nickel materials. We produce caulking wires in all sizes, while sealing strips are available in various tape thicknesses. The most popular tape thicknesses on the market are: 0.3 mm, 0.5 mm, and 0.7 mm. In addition to standard orders, we also manufacture special-shaped sealing strips with variable profiles, such as 1.8/2.5 mm or 2.0/2.5 mm. Our company offers the production of J, I, L, and U-shaped sealing strips of various diameters, ranging from 300 mm to 2000 mm, with a height of up to 16 mm and a thickness of 0.3 mm to 0.7 mm. The length of our strips when unfolded ranges from 650 mm to 8000 mm, or in spiral form to any length specified by the customer.

We are able to produce other shapes of sealing strips that meet the individual needs of our customers. Our company has engineering capabilities that allow us to independently develop tooling for the production of sealing strips with non-standard shapes. To achieve this, we utilize a roller system, which is beyond our standard equipment. This enables us to provide our customers with solutions tailored to their specific requirements and preferences.

Axial locking segments serve the purpose of protecting rotor blades from axial displacement along the rotor axis. We don’t limit ourselves to the production of standard types of segments – we also manufacture profiles tailored to the needs of our customers. The technological equipment necessary for the production of axial locking segments is made in-house. Our company specializes in producing segments of various widths, such as segment types: 5, 10, 12, 15, and 20, where the type determines the width of the detail in millimeters. Our segments are made of high-quality stainless steel, guaranteeing durability and strength to our customers. The drawing process, to which our plates are subjected, ensures not only excellent surface quality but also favorable compressive stress conditions. This, in turn, contributes to increasing the strength of our details and ensures a very good surface roughness.

Spring tapes are widely used in many industries. Their strength and flexibility allow them to be used to mount even very heavy objects. Stainless steel tapes are resistant to corrosion, sunlight, and temperature changes. In the basic version, we offer stainless steel tapes up to 350 mm wide and up to 2.5 mm thick. Carbon tapes also feature high strength and resistance to variable atmospheric conditions, but their most important characteristic is their conductivity. The most popular materials include C75S (1.1248), C67S (1.1231), and 51CrV4 (1.8159), which we configure to any required dimensions for the customer – providing cutting services to the appropriate length and width. We also fulfill custom orders according to the specifications provided by the customer.

In our product portfolio, we offer coil springs, flat springs, compression springs, and disc springs. Additionally, we fulfill custom orders to meet individual customer needs. The materials we use include typical spring steels and nickel alloys. Disc springs are exclusively manufactured by hot extrusion to the required shape (we do not use mechanical processing technology). Each produced spring undergoes testing of its deflection characteristics relative to the applied force. Upon request, we provide deflection characteristic testing of the spring in an accredited laboratory.

We also offer a wide range of assembly accessories. Our assortment includes various products such as: washers, tapes, dowels, screws, nuts, plugs, caps, gaskets, inserts, centering bushings, sliding plates, nuts, screws, spacers, mounting tapes, and many more. We ensure high quality of these elements, which are essential for effective assembly and construction. Regardless of the project or needs, our remaining range of mounting elements is ready to meet the requirements of our customers.