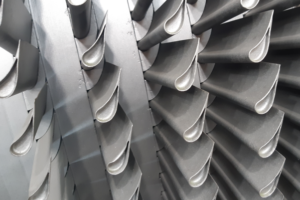

Abrasive blasting

The almost complete removal of any contamination without affecting the texture of the elements or the perfect preparation of the material for powder coating is possible thanks to abrasive blasting. We use this process at almost every stage of production, starting from cleaning semi-finished products in the delivered state from corrosion traces to cleaning after welding and heat treatments, and preparing the surface for painting. Abrasive blasting is also used for mechanically finished details to achieve a matte visual effect and, during renovations, to remove scale that forms due to long-term use. We have two chambers for this process – one with dimensions of 2800 x 5800mm and another for large-sized details with dimensions of 5300 x 8000mm.