-

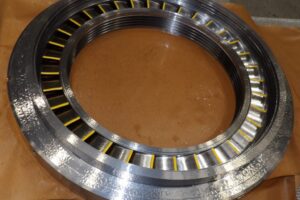

Spacer band diaphragms are mainly found in steam turbine constructions, in the HP (high-pressure) and the IP (intermediate-pressure) modules. They consist of an outer ring, an inner ring, and a blade palisade. The palisade is composed of blades whose position is determined by the inner and outer shrouds. We stand out from other manufacturers with the technology of making blade holes in the shrouds. The holes are cut in the rolled shroud using water cutting method. This ensures the proper geometry of the holes and perfect fitting to the steering blades.

We manufacture diaphragms of this type up to a diameter of 2500mm.

Typically, the blades and shrouds are made of high-alloy steel (e.g., X22CrMoV12-1, X20Cr13, X11CrMo12-1). The inner and outer rings are made of high-alloy steel for the HP module and a combination of high-alloy and low-alloy steel for the IP module (e.g., X22CrMoV12-1, 14MoV6-3, 13CrMo4-5).

All main components of the spacer band diaphragms are connected by welding. To ensure high-quality connections, we weld the palisade using the TIG method. The main welds between the rings and the palisade are made using the SAW, MAG, and MMA methods, depending on the customer’s requirements.

-

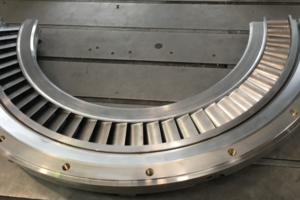

Compact diaphragms are mainly used in steam turbines, in the HP (high-pressure) module. They are built only with an outer ring and blades. Unlike standard steering blades, these blades have integral shrouds.

Diaphragms of this type typically do not exceed a diameter of 1500mm. Usually, the blades and the outer ring are made of high-alloy steel (e.g., X22CrMoV12-1, X11CrMo12-1).

The blades are connected with the outer ring by welding. The main welds are made using the SAW, MAG, and MMA methods, depending on the customer’s requirements.

-

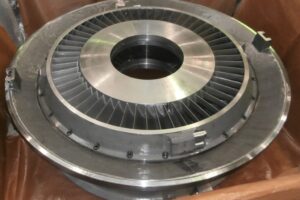

Platform diaphragms are mainly used in steam turbines, in the HP (high-pressure) module. They are built with an outer and inner ring, as well as blades. Unlike standard steering blades, these blades have integral shrouds.

Diaphragms of this type typically do not exceed a diameter of 3600mm. Most often, the blades and the outer ring are made of high-alloy steel (e.g., X22CrMoV12-1, X11CrMo12-1).

The blades with both the outer and inner rings are connected by welding. The main welds are made using the SAW, MAG, and MMA methods, depending on the customer’s requirements.

-

Fillet fab diaphragms are mainly used in steam turbines, in the IP (intermediate-pressure) and LP (low-pressure) modules. They are built with an outer and inner ring, as well as blades. The steering blades are directly welded to the rings with a fillet joints. We distinguish ourselves from other manufacturers with the technology of setting the blades forming the steam path. Thanks to a special mounting device, we ensure proper spacing and flow of the steam path.

Discs of this type are manufactured up to a diameter of 7000mm.

Typically, the blades are made of high-alloy steel (e.g., X22CrMoV12-1, X20Cr13, X11CrMo12-1). The inner and outer rings are made of high-alloy steel for the IP module (e.g., X22CrMoV12-1) and of low-alloy and structural steel for the LP module (e.g., 14MoV6-3, 13CrMo4-5, GP280GH, S355JR).

Fillet joints between the rings and the blade are performed using the TIG and MMA methods, depending on the customer’s requirements. To ensure access to welding such enormous sizes, we have developed and built a special welding positioner, which allows positioning the diaphragm in a convenient position for the welder. The natural position of the welder’s body translates into the quality of the welded joints.

-

Regulated diaphragms are mainly used in steam turbines, in the LP (low-pressure) module. They are built with an outer and inner ring, as well as a blade palisade. The palisade consists of blades, whose position is determined by the inner and outer shrouds. Unlike standard spacer band diaphragms, this type of diaphragms has a split palisade in the vertical plane of the diaphragm. The construction consists of a stationary and movable part. The rotation of the movable part causes the opening and closing of the entire steam path. To prevent the regulated diaphragm from seizing during operation, circumferential deposits, known as hard facing, are applied.

Diaphragms of this type are manufactured up to a diameter of 2500mm.

Typically, the blades and shrouds are made of high-alloy steel (e.g., X22CrMoV12-1, X20Cr13, X11CrMo12-1). The inner and outer rings are made of low-alloy and structural steel for the LP module (e.g., 14MoV6-3, 13CrMo4-5, S355JR).

All main components of the regulated diaphragms are connected by welding. To ensure high-quality connections, we weld the palisade using the TIG method. The main welds between the rings and the palisade are made using the SAW, MAG, and MMA methods, depending on the customer’s requirements. Hard facing deposits are made using the MIG method.

-

The palisade of gas turbine diaphragm is built with an outer and inner shroud, as well as blades. The steering blades are welded to the shrouds with a fillet joints. The technology of making blade holes in the shrouds is the main element that distinguishes us among other manufacturers. The holes are cut in the rolled shroud using water cutting method, ensuring proper geometry and perfect fitting to the steering blades. After welding the blade palisade, additional stiffening rings are welded.

Diaphragms of this type are manufactured up to a diameter of 2500mm.

Typically, all main components of gas turbine diaphragms are made of nickel alloys (e.g., HASTELLOY X).

Fillet joints between the blades and the shrouds are made using the TIG and MMA methods, depending on the customer’s requirements. Butt welds between the stiffening rings and the palisade are made using the MMA method.

- Spacer band diaphragms

- Compact diaphragms

- Platform diaphragms

- Fillet fab diaphragms

- Regulated diaphragms

- Gas turbine diaphragms

Spacer band diaphragms are mainly found in steam turbine constructions, in the HP (high-pressure) and the IP (intermediate-pressure) modules. They consist of an outer ring, an inner ring, and a blade palisade. The palisade is composed of blades whose position is determined by the inner and outer shrouds. We stand out from other manufacturers with the technology of making blade holes in the shrouds. The holes are cut in the rolled shroud using water cutting method. This ensures the proper geometry of the holes and perfect fitting to the steering blades.

We manufacture diaphragms of this type up to a diameter of 2500mm.

Typically, the blades and shrouds are made of high-alloy steel (e.g., X22CrMoV12-1, X20Cr13, X11CrMo12-1). The inner and outer rings are made of high-alloy steel for the HP module and a combination of high-alloy and low-alloy steel for the IP module (e.g., X22CrMoV12-1, 14MoV6-3, 13CrMo4-5).

All main components of the spacer band diaphragms are connected by welding. To ensure high-quality connections, we weld the palisade using the TIG method. The main welds between the rings and the palisade are made using the SAW, MAG, and MMA methods, depending on the customer’s requirements.

Compact diaphragms are mainly used in steam turbines, in the HP (high-pressure) module. They are built only with an outer ring and blades. Unlike standard steering blades, these blades have integral shrouds.

Diaphragms of this type typically do not exceed a diameter of 1500mm. Usually, the blades and the outer ring are made of high-alloy steel (e.g., X22CrMoV12-1, X11CrMo12-1).

The blades are connected with the outer ring by welding. The main welds are made using the SAW, MAG, and MMA methods, depending on the customer’s requirements.

Platform diaphragms are mainly used in steam turbines, in the HP (high-pressure) module. They are built with an outer and inner ring, as well as blades. Unlike standard steering blades, these blades have integral shrouds.

Diaphragms of this type typically do not exceed a diameter of 3600mm. Most often, the blades and the outer ring are made of high-alloy steel (e.g., X22CrMoV12-1, X11CrMo12-1).

The blades with both the outer and inner rings are connected by welding. The main welds are made using the SAW, MAG, and MMA methods, depending on the customer’s requirements.

Fillet fab diaphragms are mainly used in steam turbines, in the IP (intermediate-pressure) and LP (low-pressure) modules. They are built with an outer and inner ring, as well as blades. The steering blades are directly welded to the rings with a fillet joints. We distinguish ourselves from other manufacturers with the technology of setting the blades forming the steam path. Thanks to a special mounting device, we ensure proper spacing and flow of the steam path.

Discs of this type are manufactured up to a diameter of 7000mm.

Typically, the blades are made of high-alloy steel (e.g., X22CrMoV12-1, X20Cr13, X11CrMo12-1). The inner and outer rings are made of high-alloy steel for the IP module (e.g., X22CrMoV12-1) and of low-alloy and structural steel for the LP module (e.g., 14MoV6-3, 13CrMo4-5, GP280GH, S355JR).

Fillet joints between the rings and the blade are performed using the TIG and MMA methods, depending on the customer’s requirements. To ensure access to welding such enormous sizes, we have developed and built a special welding positioner, which allows positioning the diaphragm in a convenient position for the welder. The natural position of the welder’s body translates into the quality of the welded joints.

Regulated diaphragms are mainly used in steam turbines, in the LP (low-pressure) module. They are built with an outer and inner ring, as well as a blade palisade. The palisade consists of blades, whose position is determined by the inner and outer shrouds. Unlike standard spacer band diaphragms, this type of diaphragms has a split palisade in the vertical plane of the diaphragm. The construction consists of a stationary and movable part. The rotation of the movable part causes the opening and closing of the entire steam path. To prevent the regulated diaphragm from seizing during operation, circumferential deposits, known as hard facing, are applied.

Diaphragms of this type are manufactured up to a diameter of 2500mm.

Typically, the blades and shrouds are made of high-alloy steel (e.g., X22CrMoV12-1, X20Cr13, X11CrMo12-1). The inner and outer rings are made of low-alloy and structural steel for the LP module (e.g., 14MoV6-3, 13CrMo4-5, S355JR).

All main components of the regulated diaphragms are connected by welding. To ensure high-quality connections, we weld the palisade using the TIG method. The main welds between the rings and the palisade are made using the SAW, MAG, and MMA methods, depending on the customer’s requirements. Hard facing deposits are made using the MIG method.

The palisade of gas turbine diaphragm is built with an outer and inner shroud, as well as blades. The steering blades are welded to the shrouds with a fillet joints. The technology of making blade holes in the shrouds is the main element that distinguishes us among other manufacturers. The holes are cut in the rolled shroud using water cutting method, ensuring proper geometry and perfect fitting to the steering blades. After welding the blade palisade, additional stiffening rings are welded.

Diaphragms of this type are manufactured up to a diameter of 2500mm.

Typically, all main components of gas turbine diaphragms are made of nickel alloys (e.g., HASTELLOY X).

Fillet joints between the blades and the shrouds are made using the TIG and MMA methods, depending on the customer’s requirements. Butt welds between the stiffening rings and the palisade are made using the MMA method.