Valves

We have been involved in the production of turbine valves from the very beginning – it is one of the key products of Metal Expert. Years of technical knowledge, appropriate production equipment, and qualified personnel are the essential foundation for manufacturing this product. In the production of turbine valves, we are not limited by any special processes, and we ensure comprehensive delivery.

-

We provide comprehensive services for the pre-assembly and main assembly of valves.

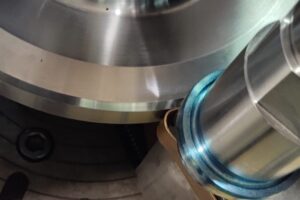

During assembly, depending on the valve’s construction, press-fit components are either cooled in liquid nitrogen or heated in a furnace to ensure uniform heating of the part. In collaborating valve parts that serve the closing function, the stroke is examined, and then the sealing surfaces undergo a lapping control to check their alignment.

Assembled elements are tightened with the required torque values and secured with appropriately selected adhesives from Loctite or welded to prevent loosening during operation.

Valve components include items such as guides, screens, pins, sealing elements, washers, threaded components, spindles, closures (locks), diffusers, sleeves, and more.

Our standard valve components are typically within the size of Ø800×2000, but we can handle larger sizes as well.

-

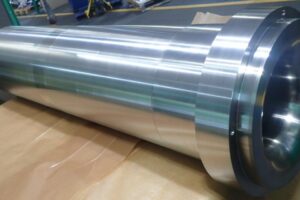

Spindles, as long and fine components, require special manufacturing technology and high attention to detail. Deviations from tolerances, such as radial runout, can lead to extreme damages. Therefore, we subject our spindles to one hundred percent inspection. Maintaining tolerances is particularly challenging on sliding surfaces where hardened welds, sprayed coatings, or nitrided layers are present.

-

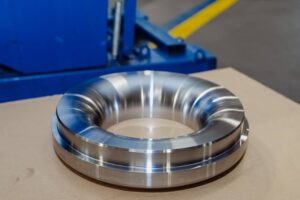

Diffusers are components that directly interact with turbines, so the requirements related to their manufacturing are extremely strict. A characteristic feature of diffusers is the welds on the surface of the sphere, which serve a closing function. Achieving the sharpest tolerance requirements is crucial during the production of this component. As a company, we hold a full range of welding qualifications according to European and American standards, as well as customer-specific industry specifications.

-

Among valve components, thin-walled bushes are the most challenging to manufacture, partly due to the presence of hardfaced welds, sprayed coatings, and nitrided layers on them. When producing such details, it is easy to lead to their ovalization during mechanical processing. Precision and attention to detail are crucial for the proper production of this component.

-

The diversity of parts we manufacture for turbine valves is extensive. We produce components ranging from very small sizes, such as screws, pins, bushings, inserts, dowels, sliding plates, to larger ones, including, seats, spindle heads, spindle guide bodies, and valve discs. Among the largest details are valve bells, valve shafts, and spindle carriers.

We provide comprehensive services for the pre-assembly and main assembly of valves.

During assembly, depending on the valve’s construction, press-fit components are either cooled in liquid nitrogen or heated in a furnace to ensure uniform heating of the part. In collaborating valve parts that serve the closing function, the stroke is examined, and then the sealing surfaces undergo a lapping control to check their alignment.

Assembled elements are tightened with the required torque values and secured with appropriately selected adhesives from Loctite or welded to prevent loosening during operation.

Valve components include items such as guides, screens, pins, sealing elements, washers, threaded components, spindles, closures (locks), diffusers, sleeves, and more.

Our standard valve components are typically within the size of Ø800×2000, but we can handle larger sizes as well.

Spindles, as long and fine components, require special manufacturing technology and high attention to detail. Deviations from tolerances, such as radial runout, can lead to extreme damages. Therefore, we subject our spindles to one hundred percent inspection. Maintaining tolerances is particularly challenging on sliding surfaces where hardened welds, sprayed coatings, or nitrided layers are present.

Diffusers are components that directly interact with turbines, so the requirements related to their manufacturing are extremely strict. A characteristic feature of diffusers is the welds on the surface of the sphere, which serve a closing function. Achieving the sharpest tolerance requirements is crucial during the production of this component. As a company, we hold a full range of welding qualifications according to European and American standards, as well as customer-specific industry specifications.

Among valve components, thin-walled bushes are the most challenging to manufacture, partly due to the presence of hardfaced welds, sprayed coatings, and nitrided layers on them. When producing such details, it is easy to lead to their ovalization during mechanical processing. Precision and attention to detail are crucial for the proper production of this component.

The diversity of parts we manufacture for turbine valves is extensive. We produce components ranging from very small sizes, such as screws, pins, bushings, inserts, dowels, sliding plates, to larger ones, including, seats, spindle heads, spindle guide bodies, and valve discs. Among the largest details are valve bells, valve shafts, and spindle carriers.