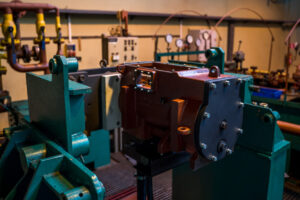

We perform comprehensive servomotor assemblies. For this purpose, we have designated and dedicated special stand our machine park. During the assembly of servomotors, the alignment of their critical surfaces is checked using the bluing method (Blue print test), and the screw connections are tightened using a torque wrench. The final stage of this process involves installing externally purchased pressure and flow control electrical systems along with all cabling. We work with parts from manufacturers such as MOOG and VICKERS.

The servomotor comprises the following components:

- Housings

- Pistons

- Disc springs

- Covers

- Flanges

- Boltings