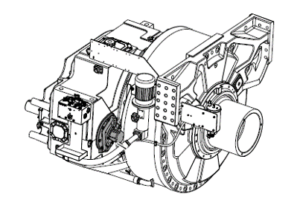

Wind turbines

Maintaining wind turbines along with their associated installations in proper condition is a significant challenge. The primary goal of wind turbine maintenance is to extend its operational uptime between planned shutdowns and minimize the risk of failures.

As a company with extensive experience in repairs, we can offer a range of services related to wind turbine maintenance.

-

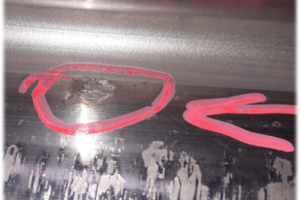

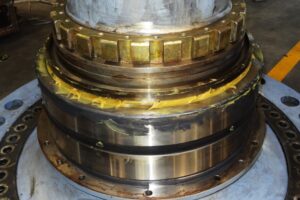

Non-destructive testing allows for the detection of all types of defects and cracks, which can be very dangerous for the equipment. A broken piece can cause cascading damage throughout the entire gearbox area.

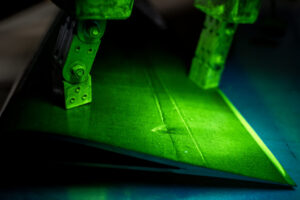

The non-destructive testing (NDT) methods we use include:

- Visual inspection

- Magnetic particle testing

- Penetrant testing

- Ultrasonic testing

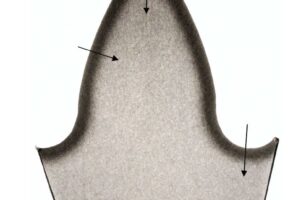

- Radiographic testing

- Endoscopic testing

-

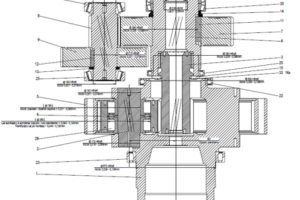

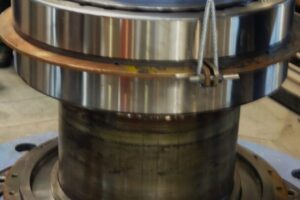

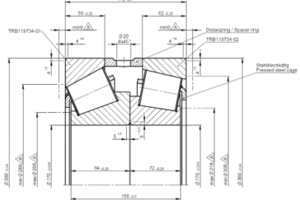

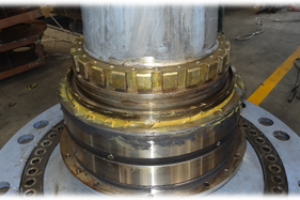

The wind turbine also contains various standardized components, such as gaskets, rings, seals, screws, washers, nuts, etc. However, the main and most important standardized components are bearings. Through collaboration with leading bearing manufacturers, we are able to select and replace them with new ones accordingly.

-

Comprehensive assembly includes:

- Steam cleaning of all parts directly before assembly

- Degreasing the meshing of teeth

- Securing screws with adhesive to prevent loosening due to vibrational nature of operation

- Tightening screws to the appropriate torque

- Ensuring proper bearing clearances

- Bearing assembly while adhering to temperature regime guidelines

- Disassembly

- Non-destructive testing

- Destructive testing

- Measurements

- Technical condition assessment

- Re-engineering of defective components

- Replacement of standardized components

- Assembly

Non-destructive testing allows for the detection of all types of defects and cracks, which can be very dangerous for the equipment. A broken piece can cause cascading damage throughout the entire gearbox area.

The non-destructive testing (NDT) methods we use include:

- Visual inspection

- Magnetic particle testing

- Penetrant testing

- Ultrasonic testing

- Radiographic testing

- Endoscopic testing

The wind turbine also contains various standardized components, such as gaskets, rings, seals, screws, washers, nuts, etc. However, the main and most important standardized components are bearings. Through collaboration with leading bearing manufacturers, we are able to select and replace them with new ones accordingly.

Comprehensive assembly includes:

- Steam cleaning of all parts directly before assembly

- Degreasing the meshing of teeth

- Securing screws with adhesive to prevent loosening due to vibrational nature of operation

- Tightening screws to the appropriate torque

- Ensuring proper bearing clearances

- Bearing assembly while adhering to temperature regime guidelines