Quality

Each one of us is responsible for quality.

-

To ensure high-quality end products, we have implemented a series of procedures and instructions at every stage of production, from material acceptance through manufacturing to packaging, storage, and transportation.

Tasks related to inspection, measurements, and testing are carried out only by authorized personnel, and it is the duty of every employee to report products and materials that do not meet requirements. Each of us is responsible for quality.

We have qualified quality controllers and NDT inspection operators, including operators with the highest, third-level qualifications. Quality control during manufacturing is also carried out through self-inspection, which is only authorized for selected employees with extensive experience, who are specialists in their respective areas.

Every stage of production undergoes inspection. Detailed quality criteria are described in the workshop documents issued before production begins – technological guides. The results of the inspection are documented.

If any non-conformities are found, the production process is suspended, and the non-compliant product is subject to actions according to the procedure for monitoring non-conforming products.

Final inspection of the products is conducted after completion of the manufacturing process and all planned measurement and testing controls with a positive result. In special cases, such as production for the nuclear market, we perform a two-stage inspection, also involving third-party stakeholders.

-

Our system for the use, control, and calibration of tools and measuring instruments places us at the highest level of precision and repeatability in measurements, giving our customers confidence in receiving components that meet their technical specifications. Precise measurement is one of the most important activities in detail production, which is why it is essential for professionals to have measuring tools they can always rely on.

Small components are measured manually using standard measuring tools. For components of medium and large dimensions, we use the Leica Tracker 3D laser tracker. This is a portable coordinate measuring machine (CMM) that provides the highest precision even over very large distances.

-

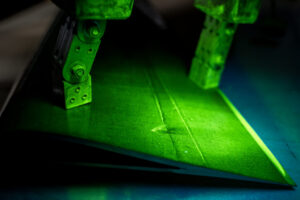

Non-destructive testing (NDT) encompasses a variety of inspection techniques used to detect flaws and assess the condition of materials in a non-destructive manner. These techniques are commonly employed in various industries such as steel construction, energy, petrochemicals, shipbuilding, and others. They are primarily used to examine welded joints, soldered connections, castings, and forgings.

The diversity of objects examined stems from the wide range of available NDT techniques, which allow for the selection of the appropriate method and specialized approach in virtually every case. Due to the phenomena utilized and the capabilities of individual techniques, we can distinguish the following types of non-destructive testing conducted by our personnel:

- Visual testing (VT)

- Magnetic particle testing (MT)

- Ulstrasonic testing (UT)

- Liquid penetrate testing (PT)

The company’s focus on its employees has resulted in commitment, competence development, and qualifications enhancement of our workforce, leading to the overall development of the entire company. Through stable employment, organized work processes, and experience, our clients can feel fully secure and have confidence in the reliability of the NDT inspections conducted by the qualified personnel of our company. The qualifications and competencies of our quality control staff performing NDT inspections are as follows:

NDT operator 1 – Certificate – Inspection range

02898-VT2 Grade 2 visual examination (vt-2)

02898-UT2 Grade 2 ultrasonic testing (ut-2)

02898-PT2 Grade 2 penetrant testing (pt-2)

02898-MT2 Grade 2 magnetic particle testing (mt-2)

02898-MT3 Grade 3 magnetic particle testing (mt-3)

02898-PT3 Grade 3 penetrant testing (pt-3)

02898-UT3 Grade 3 ultrasonic testing (ut-3)

NDT operator 2 – Certificate – Inspection range

02119-VT2 Grade 2 visual examination (vt-2)

02119-UT2 Grade 2 ultrasonic testing (ut-2)

02119-MT2 Grade 2 magnetic particle testing (mt-2)

02119-PT2 Grade 2 penetrant testing (pt-2)NDT operator 3 – Certificate – Inspection range

03103-VT2 Grade 2 visual examination (vt-2)NDT operator 4 – Certificate – Inspection range04452-UT2 Grade 2 ultrasonic testing (ut-2)

04452-MT2 Grade 2 magnetic particle testing (mt-2)

04452-VT2 Grade 2 visual examination (vt-2)

04452-PT2 Grade 2 penetrant testing (pt-2)NDT inspections, as well as destructive testing in specific cases (e.g., manufacturing components for nuclear projects, chemical industry, etc.), may require confirmation or conduct of these tests by independent institutions upon the client’s request.

In this regard, Metal Expert collaborates on an ongoing basis with independent, recognized, and accredited (in accordance with the requirements of the PN-EN ISO/IEC 17025 standard) organizations and laboratories with a global scope.

We also collaborate with reputable classification societies such as BV, DNV GL, ABS, LR, TUV, SLV, PRS, UDT.

To ensure high-quality end products, we have implemented a series of procedures and instructions at every stage of production, from material acceptance through manufacturing to packaging, storage, and transportation.

Tasks related to inspection, measurements, and testing are carried out only by authorized personnel, and it is the duty of every employee to report products and materials that do not meet requirements. Each of us is responsible for quality.

We have qualified quality controllers and NDT inspection operators, including operators with the highest, third-level qualifications. Quality control during manufacturing is also carried out through self-inspection, which is only authorized for selected employees with extensive experience, who are specialists in their respective areas.

Every stage of production undergoes inspection. Detailed quality criteria are described in the workshop documents issued before production begins – technological guides. The results of the inspection are documented.

If any non-conformities are found, the production process is suspended, and the non-compliant product is subject to actions according to the procedure for monitoring non-conforming products.

Final inspection of the products is conducted after completion of the manufacturing process and all planned measurement and testing controls with a positive result. In special cases, such as production for the nuclear market, we perform a two-stage inspection, also involving third-party stakeholders.

Our system for the use, control, and calibration of tools and measuring instruments places us at the highest level of precision and repeatability in measurements, giving our customers confidence in receiving components that meet their technical specifications. Precise measurement is one of the most important activities in detail production, which is why it is essential for professionals to have measuring tools they can always rely on.

Small components are measured manually using standard measuring tools. For components of medium and large dimensions, we use the Leica Tracker 3D laser tracker. This is a portable coordinate measuring machine (CMM) that provides the highest precision even over very large distances.

Non-destructive testing (NDT) encompasses a variety of inspection techniques used to detect flaws and assess the condition of materials in a non-destructive manner. These techniques are commonly employed in various industries such as steel construction, energy, petrochemicals, shipbuilding, and others. They are primarily used to examine welded joints, soldered connections, castings, and forgings.

The diversity of objects examined stems from the wide range of available NDT techniques, which allow for the selection of the appropriate method and specialized approach in virtually every case. Due to the phenomena utilized and the capabilities of individual techniques, we can distinguish the following types of non-destructive testing conducted by our personnel:

- Visual testing (VT)

- Magnetic particle testing (MT)

- Ulstrasonic testing (UT)

- Liquid penetrate testing (PT)

The company’s focus on its employees has resulted in commitment, competence development, and qualifications enhancement of our workforce, leading to the overall development of the entire company. Through stable employment, organized work processes, and experience, our clients can feel fully secure and have confidence in the reliability of the NDT inspections conducted by the qualified personnel of our company. The qualifications and competencies of our quality control staff performing NDT inspections are as follows:

02898-VT2 Grade 2 visual examination (vt-2)

02898-UT2 Grade 2 ultrasonic testing (ut-2)

02898-PT2 Grade 2 penetrant testing (pt-2)

02898-MT2 Grade 2 magnetic particle testing (mt-2)

02898-MT3 Grade 3 magnetic particle testing (mt-3)

02898-PT3 Grade 3 penetrant testing (pt-3)

02898-UT3 Grade 3 ultrasonic testing (ut-3)

NDT operator 2 – Certificate – Inspection range

02119-VT2 Grade 2 visual examination (vt-2)

02119-UT2 Grade 2 ultrasonic testing (ut-2)

02119-MT2 Grade 2 magnetic particle testing (mt-2)

02119-PT2 Grade 2 penetrant testing (pt-2)

03103-VT2 Grade 2 visual examination (vt-2)

04452-MT2 Grade 2 magnetic particle testing (mt-2)

04452-VT2 Grade 2 visual examination (vt-2)

04452-PT2 Grade 2 penetrant testing (pt-2)

NDT inspections, as well as destructive testing in specific cases (e.g., manufacturing components for nuclear projects, chemical industry, etc.), may require confirmation or conduct of these tests by independent institutions upon the client’s request.

In this regard, Metal Expert collaborates on an ongoing basis with independent, recognized, and accredited (in accordance with the requirements of the PN-EN ISO/IEC 17025 standard) organizations and laboratories with a global scope.

We also collaborate with reputable classification societies such as BV, DNV GL, ABS, LR, TUV, SLV, PRS, UDT.