Welded constructions

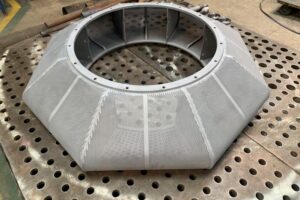

The primary sector for which we manufacture steel structures is the energy sector. Our steel structures are utilized in conventional, nuclear, and hydroelectric power plants, among others. Welding in our company is performed according to EN 1090 and ISO 3834-2 standards. We have production capabilities for manufacturing both small precision structures and large-scale structures. We are able to meet the high requirements and expectations of every customer and fulfill orders with a high degree of complexity.

-

The range of structures we manufacture is very wide. We produce not only simple steel structures but also structures with much more complex shapes. We offer welded constructions within the following limits:

- Maximum dimensions: 5500mm x 5000mm x 12000mm

- Maximum weight: 50 tons

We manufacture welded constructions from structural steel, low-alloy steel, high-alloy steel, austenitic steel, and other alloy materials. In addition to assembly and welding of details, we offer additional services such as design, pressure testing, load testing, NDT inspections, and leak testing. Detailed information about the welding processes we use can be found here.

-

The production process of individual pipeline components is carried out in accordance with safety requirements and applicable technical norms and standards. We primarily use purchased semi-finished products for pipeline prefabrication. In the case of non-standardized semi-finished products, we produce them ourselves. After preliminary assembly and welding, the geometry of the pipelines is always measured using a Leica laser tracker, ensuring precise spatial measurement of the pipelines.

The most commonly used materials for pipeline production include: P235GH, P265GH, 13CrMo4-5, 10CrMo9-10, X10CrMoVNb9-1, X5CrNi18-10, X6CrNiTi18-10, X6CrNiMoTi17-12-2.

In accordance with the characteristics of the pipelines and customer requirements, we also conduct pressure tests. For this type of service, we develop and manufacture the necessary equipment ourselves.

-

We offer the production of transport frames for rotors and casings according to individual customer needs. In addition to manufacturing, we provide design services and additional tests, such as load tests or non-destructive testing (NDT) of welds. All our products undergo thorough examination and testing and come with full certification. The entire process of design, production, and testing is carried out with a notified body.

-

We manufacture turbine valve chambers and connectors in welded construction. Our design office is capable of converting cast constructions into welded ones to shorten delivery times. Just like with all welded constructions, we conduct comprehensive non-destructive testing (NDT) and pressure tests up to 60 MPa.

-

We also provide custom welded structures tailored to individual customer needs. Non-standard welded structures are often highly flexible and require considerable attention and time to achieve the desired result. We are capable of executing these structures comprehensively, from design and assembly to welding, heat treatment, mechanical processing, as well as testing and inspections.

-

In addition to the already mentioned structures, we also offer the production of various customized components according to the customer’s needs. So far, we have produced welded constructions such as:

- Strainers

- Thermal shields

- Screens

- Insection port housings

- Storage racks

- Covering hoods

- Embedments

- Blow-off channels

- Ladders

- Railings

- Brackets

- Frameworks

- Platforms

- Compensators

- Manufacturing capabilities

- Oil system

- Pipelines

- Transport frames

- Valve chambers and connectors (intermediate pieces)

- Non-standard structures

- Others

|

Zakres realizowanych przez nas konstrukcji jest bardzo szeroki. Wykonujemy nie tylko proste konstrukcje stalowe, ale również konstrukcje o dużo bardziej złożonych kształtach. Oferujemy konstrukcje spawane w poniższym zakresie:

Konstrukcje spawane wykonujemy ze stali konstrukcyjnych, niskostopowych, wysokostopowych, austenitycznych oraz innych materiałów stopowych. Poza montażem i spawaniem detali oferujemy usługi dodatkowe, takie jak: projektowanie, próby ciśnieniowe, próby obciążeniowe, badania NDT, badania szczelności. Szczegółowe informacje stosowanych przez nas procesów spawalniczych można znaleźć tutaj. |

The production process of individual pipeline components is carried out in accordance with safety requirements and applicable technical norms and standards. We primarily use purchased semi-finished products for pipeline prefabrication. In the case of non-standardized semi-finished products, we produce them ourselves. After preliminary assembly and welding, the geometry of the pipelines is always measured using a Leica laser tracker, ensuring precise spatial measurement of the pipelines.

The most commonly used materials for pipeline production include: P235GH, P265GH, 13CrMo4-5, 10CrMo9-10, X10CrMoVNb9-1, X5CrNi18-10, X6CrNiTi18-10, X6CrNiMoTi17-12-2.

In accordance with the characteristics of the pipelines and customer requirements, we also conduct pressure tests. For this type of service, we develop and manufacture the necessary equipment ourselves.

We offer the production of transport frames for rotors and casings according to individual customer needs. In addition to manufacturing, we provide design services and additional tests, such as load tests or non-destructive testing (NDT) of welds. All our products undergo thorough examination and testing and come with full certification. The entire process of design, production, and testing is carried out with a notified body.

We manufacture turbine valve chambers and connectors in welded construction. Our design office is capable of converting cast constructions into welded ones to shorten delivery times. Just like with all welded constructions, we conduct comprehensive non-destructive testing (NDT) and pressure tests up to 60 MPa.

We also provide custom welded structures tailored to individual customer needs. Non-standard welded structures are often highly flexible and require considerable attention and time to achieve the desired result. We are capable of executing these structures comprehensively, from design and assembly to welding, heat treatment, mechanical processing, as well as testing and inspections.

In addition to the already mentioned structures, we also offer the production of various customized components according to the customer’s needs. So far, we have produced welded constructions such as:

- Strainers

- Thermal shields

- Screens

- Insection port housings

- Storage racks

- Covering hoods

- Embedments

- Blow-off channels

- Ladders

- Railings

- Brackets

- Frameworks

- Platforms

- Compensators